The Challenge

A leading semiconductor fabrication plant required a critical upgrade to its Ultra-Pure Water (UPW) circulation loop. The existing pumps introduced measurable particles and ionic contamination, risking microscopic defects on wafers. Any downtime or performance fluctuation in this system could directly lead to massive yield losses and production delays in a 24/7 operation.

Solution

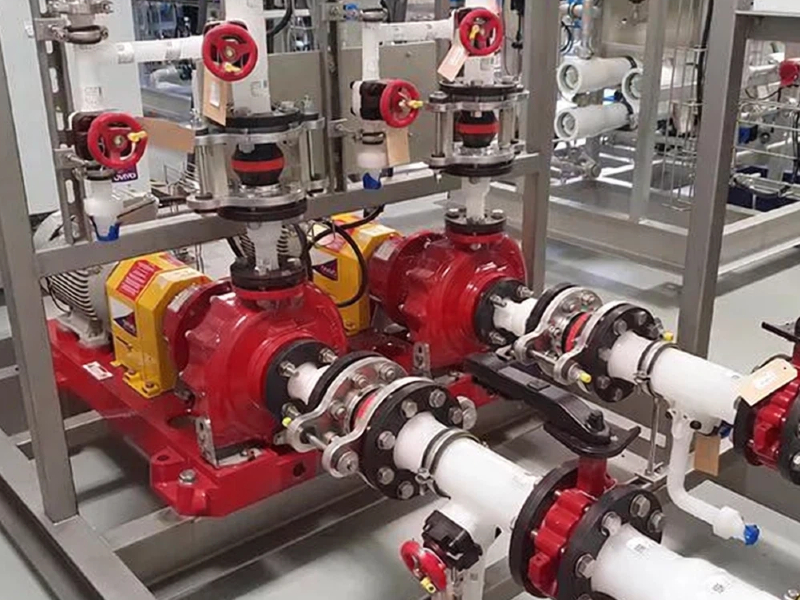

Arkstar designed and delivered a bespoke high-purity ARKSTAR Series centrifugal pump system. The pumps were constructed with electropolished 316L stainless steel and featured non-shedding, flushable mechanical seals to minimize particle generation. The entire fluid path was designed for zero stagnation and optimized for minimal internal turbulence, ensuring the water’s 18.2 MΩ·cm resistivity and particle counts were maintained to the strictest SEMI standards throughout the distribution loop.

The Value Delivered

The system provided uncompromising purity and unmatched reliability, becoming a cornerstone for the fab’s advanced process nodes. It contributed to a measurable reduction in wafer defect rates and eliminated unplanned downtime related to the UPW system, safeguarding billions of dollars in potential production value. This established Arkstar as a trusted partner for mission-critical fluid handling in high-tech manufacturing.