The Challenge:

A jam manufacturer needed to transfer viscous, fruit-particulate-laden product from storage to filling lines. Existing equipment caused excessive shear (damaging fruit pieces), was difficult to clean thoroughly, and the connecting hoses were not rated for both food safety and the required pressure, creating sanitation and integrity risks.

Solution:

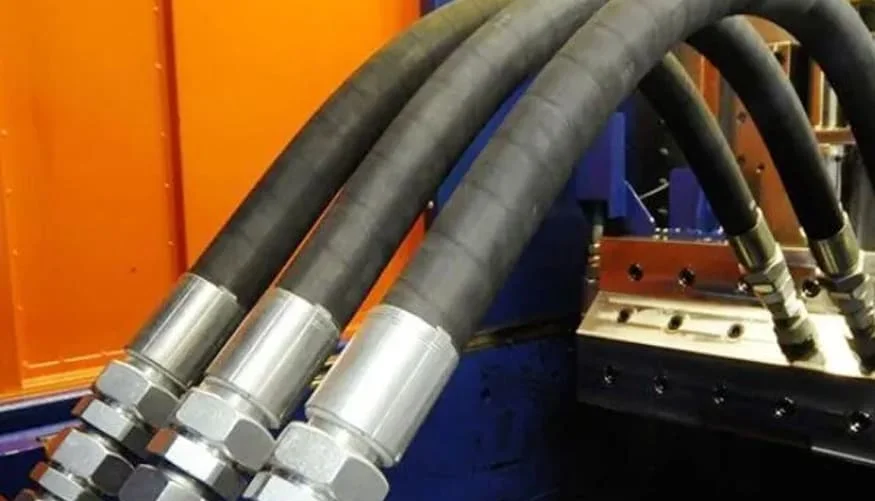

Arkstar supplied a complete, hygienic transfer solution featuring a sanitary-grade ARKFLO Series piston diaphragm pump and food-grade, high-pressure ARKFLEX Series hoses. The pump’s low-shear action preserved product integrity, while both the pump (polished stainless steel, 3-A compliant) and the specially formulated hoses were designed for full Clean-in-Place (CIP) capability, ensuring no bacteria-harboring

The Value Delivered:

The integrated system preserved the premium texture and quality of the final product by protecting fruit pieces and preventing contamination. It exceeded stringent food safety audit requirements for both pumping and conveying components. The easy-to-clean design of the entire loop increased production line flexibility and reduced changeover time significantly.