1 The Evolution of Rubber Hose Production

2 Material Selection and Compound Preparation

3 Extrusion Technologies for Hose Production

-

Hot extrusion, the most common method, involves heating rubber until it becomes soft and moldable, then vulcanizing it after extrusion . -

Co-extrusion allows simultaneous extrusion of multiple rubber layers through a single die, enabling combinations of materials with different properties . -

Reinforced extrusion incorporates textile or metal reinforcements during the extrusion process, essential for high-pressure hoses .

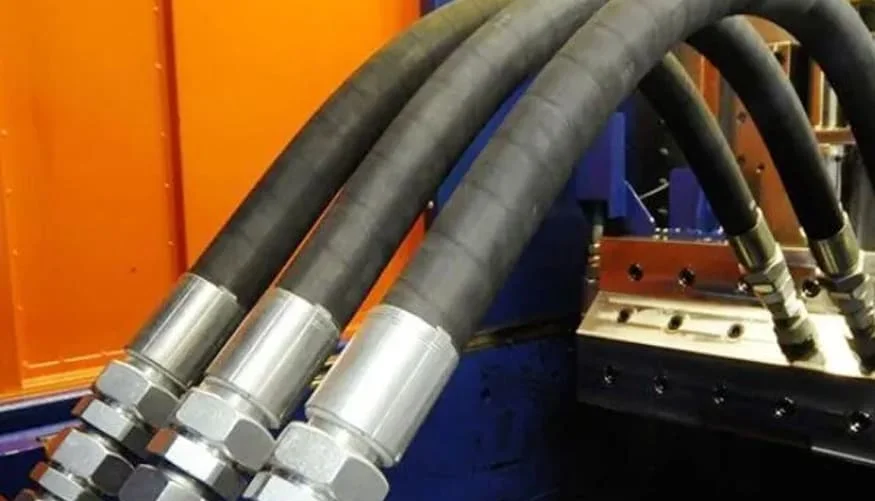

4 Reinforcement Methods for Enhanced Performance

-

Braiding, where yarns or wires are interwoven in a crisscross pattern around the hose using braiding machines . -

Spiral winding, which applies reinforcement in a helical pattern, offering superior resistance to expansion under pressure . -

Knitting, creating a looser structure that provides good flexibility with moderate pressure resistance . -

Textile wrapping, where reinforcement sheets are wrapped around the hose .

5 Vulcanization Processes and Systems

-

Continuous vulcanization using salt baths or fluidized beds for constant cross-linking of extruded hoses . -

Autoclave vulcanization, where hose lengths are wound on drums and placed in large pressurized vessels for batch processing . -

Microwave vulcanization systems that use microwave energy to rapidly heat the hose from within, significantly reducing curing times . -

Lead vulcanization, where the hose is covered with a lead sheath that is stripped after curing .

6 Quality Control and Testing Protocols

-

Hydrostatic pressure testing, where hoses are subjected to pressures significantly exceeding rated working pressure to verify structural integrity . -

Burst pressure testing that determines the ultimate failure point, with quality hoses typically having a safety factor of 3:1 or 4:1 between burst pressure and working pressure . -

Adhesion testing to measure bond strength between different layers . -

Flexibility and bend radius testing to ensure the hose can operate within specified bending limits without kinking .

7 Advanced Manufacturing Innovations

-

Smart hose technologies featuring integrated sensors for pressure, temperature, and wear monitoring . -

Advanced polymer compounds including nanocomposites that offer enhanced barrier properties and durability . -

Sustainable manufacturing initiatives focusing on energy-efficient processes, recycled materials, and biodegradable formulations . -

Additive manufacturing applications for producing custom fittings and complex hose assemblies .